Welcome to Matrix Education

To ensure we are showing you the most relevant content, please select your location below.

Select a year to see courses

Learn online or on-campus during the term or school holidays

Learn online or on-campus during the term or school holidays

Learn online or on-campus during the term or school holidays

Learn online or on-campus during the term or school holidays

Learn online or on-campus during the term or school holidays

Learn online or on-campus during the term or school holidays

Learn online or on-campus during the term or school holidays

Get HSC Trial exam ready in just a week

Get HSC exam ready in just a week

Select a year to see available courses

Science guides to help you get ahead

Science guides to help you get ahead

Need to get your motor running, but need a jumpstart? Don't worry, this video will get it all fired up.

Join 75,893 students who already have a head start.

"*" indicates required fields

You might also like

Related courses

Join 8000+ students each term who already have a head start on their school academic journey.

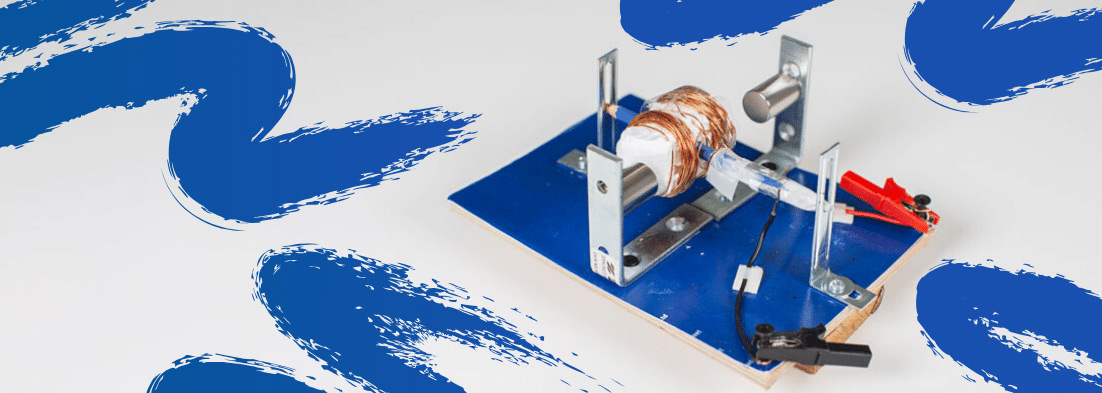

Need to build a DC Motor for your HSC Physics Practical? Worried that your motor will be all powered up with nowhere to spin? Well, don’t worry! In this post, Physics guru Tom Dixon will show you how to build a DC motor. To help you get your motor running, we’ve written up a step-by-step guide so you can make sure your experiment is all torque and not just all talk!

In this video, I explain how to build your DC Motor. For this practical assessment, you’ll first need to get the following items:

Download the Matrix Practical Skills Workbook and sharpen your Physics skills. Learn how to:

Get exam-ready for your Physics practical assessments with this FREE practical skills workbook. Fill out your details below to get this resource emailed to you. "*" indicates required fields

Sharpen your Physics skills

Sharpen your Physics skills

Once you’ve got this together, your ready to build your motor.

Let me show you how:

How to Build a DC Motor from Matrix Education on Vimeo.

Get ahead of your peers with our Year 12 Physics Matrix Course. With advanced completion of contents before it’s taught at school, you’ll be better prepared for your school assessments. Learn more about Year 12 Physics.

Physics doesn't need to be confusing

Expert teachers, detailed feedback, one-to-one help! Learn from home with Matrix+ Online Courses.

In case you want to follow a step-by-step guide, we’ve included the steps for building the motor below.

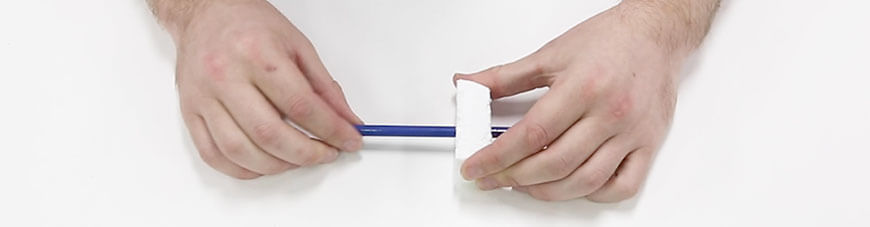

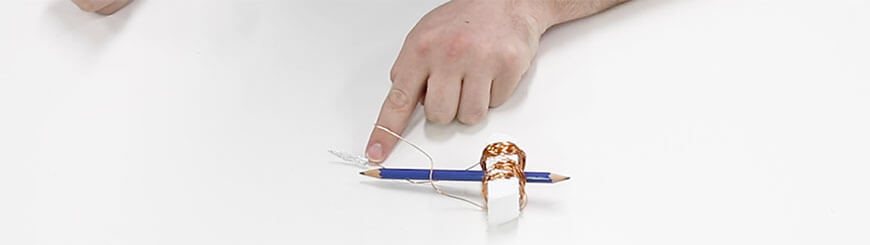

First, you need to build your coil base.

To do this, insert your pencil through the styrofoam. You want to make sure that the foam sits about a quarter of the way along the pencil.

You’re now ready to dress it with the copper coil.

First, you want to strip the end of the wire so it conducts electricity effectively. To do this sand down the ends using the sandpaper.

Then, wrap the copper wire around the base. When wrapping the styrofoam, I prefer to wrap one side and then the other. You want to make sure that both sides are evenly wrapped.

Remember, the more turns of the wire, the more torque your motor will generate!

Now you’ve wrapped the base, test the wires with your multimeter set to ‘beep’ mode (this is also called ‘continuity’ mode).

To do a “beep-test,’ touch each lead of the multimeter (making sure it’s in ‘beep’ mode) to a different end of the coil – do you hear a beep?

If you don’t hear a beep, your connections aren’t working. You need to sand the ends down further. Use the sandpaper to really rough up the ends of the wires.

Test the wires after further sanding. If they still don’t conduct, wear them back until they do.

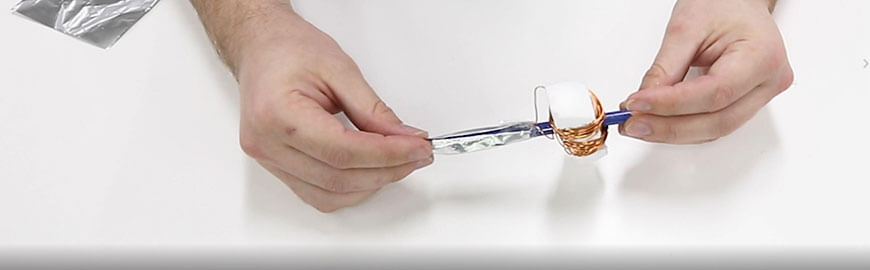

Cut two strips of aluminium foil about 1.5 cm wide and long enough to wrap around the wire tips several times.

Wrap the ends with the foil. Make sure you wrap the foil tightly around the end. You can use sticky tape to secure it, but you must ensure that you only use a thin piece and don’t interfere with the electrical connection.

Now we’ve built the base, we need to double check the connections to make sure they conduct.

Grab your multimeter and conduct another beep test to ensure the wire is conducting.

Do you hear a beep? Yes. Then you’re ready to build your commutator.

For this, you’ll need two pieces of aluminium foil to wrap the styrofoam and copper coil. You’ll need to make two half-circles of foil that run along the length of your axle. Stick these down on top of the wire-ends. You’ll then sticky tape this to the side of the pencil.

You must align the commutator and coil correctly.

Remember: When the coil is horizontal in the maximum torque position your commutator should be in electircal contact.

You want the two electrical contacts to be at contact when the torque is at maximum.

Similarly, when the coil (and this is the coil, not the styrofoam) is vertical you want the gaps in the commutator horizontal.

Make sure you set the coil correctly. When the coil is horizontal, you want the commutator to be horizontal.

Follow this process to build the commutator:

You should now have a pencil that is wrapped with two strips of foil and a thin gap between them running from tip to styrofoam. See the screenshot below if you’re unsure.

The stator is the base if the motor. Stator is a word derived from “stationary” and “rotor” on the pattern of “rotor.”

Your stator needs to hold your rotor in place while it spins.

You’ll need to use your angled brackets with slots for the axial direction of the motor (ie, the long side and not the wide side of the wood).

Now you’ve built the stator, you’re ready to attach the wires for the current.

Now you’ve got the rotor and stator for your DC motor, you need to get it powered up. Like Iron Man without his arc reactor, your motor won’t do much unless it is powered up.

Now your motor is wired, it’s ready for its final tests.

Take the multimeter and beep test the connections to make sure they function.

Double check the commutator and the connection from the screws to the stiff electrical wire.

Now you’ve built the rotator and stator and put them together, you’re ready to get things rolling.

First, affix the magnets to the regular angled brackets.

Make sure that you have enough room between the magnets for your rotor to spin!

Next, connect your power supply’s alligator clips to the conductive screws.

Turn the power on. Don’t be disappointed if it doesn’t kick off on its own; the coil is heavy.

If your motor doesn’t spin on its own – it may just rock a little – you need to give it a little nudge to get it ticking over.

Congratulations, you’ve just built your first DC motor!

Now you’ve built a motor, you need to know how to troubleshoot it so you can guarantee that it will work on the day. In our next post, we’ll show you the Top 5 Student Mistakes when Building a DC Motor and how to fix them!

Written by Tom Dixon

Tom is a PhD Student in laser physics at the University of New South Wales, with a Bachelor's Degree in Aerospace Engineering and Physics. Tom teaches computational and experimental physics to final year undergraduates at UNSW, as well as HSC Physics at Matrix Education.© Matrix Education and www.matrix.edu.au, 2025. Unauthorised use and/or duplication of this material without express and written permission from this site’s author and/or owner is strictly prohibited. Excerpts and links may be used, provided that full and clear credit is given to Matrix Education and www.matrix.edu.au with appropriate and specific direction to the original content.